Collection: Playground Shades & Sails

-

Square Hip Shade

SD101008IGRegular price $0.00 USDRegular priceUnit price / per

SD101008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

8'

Shade Size Maximum

60'

-

Rectangle Hip Shade

RD101208IGRegular price $0.00 USDRegular priceUnit price / per

RD101208IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

60'

-

Hexagon Hip Shade

HD202008IGRegular price $0.00 USDRegular priceUnit price / per

HD202008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

12'

Shade Size Maximum

55'

-

Multi-Dome Hip Shade

Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

500'

-

Square Umbrella Shade

SU101008IGRegular price $0.00 USDRegular priceUnit price / per

SU101008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

8'

Shade Size Maximum

30'

-

Hexagon Umbrella Shade

HU101008IGRegular price $0.00 USDRegular priceUnit price / per

HU101008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

8'

Shade Size Maximum

30'

-

Hypar Umbrella Shade

HYU101008IGRegular price $0.00 USDRegular priceUnit price / per

HYU101008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

27'

-

Square Cantilever Umbrella Shade

CU080808INRegular price $0.00 USDRegular priceUnit price / per

CU080808INRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

8'

Shade Size Maximum

24'

-

Dual Column Umbrella Shade

RU161208IGRegular price $0.00 USDRegular priceUnit price / per

RU161208IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

24'

-

Hexagon Cantilever Umbrella Shade

Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

8'

Shade Size Maximum

60'

-

Hanging Cantilever Shade

HC201008IGRegular price $0.00 USDRegular priceUnit price / per

HC201008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

24'

-

Standard Cantilever Shade

RC201809IGRegular price $0.00 USDRegular priceUnit price / per

RC201809IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

9' & 10'

Shade Size Minimum-

18'

Shade Size Maximum

36'

-

Arched Cantilever Shade

Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

100'

-

Isosceles Triangle Sail Shade

IS15152108Regular price $0.00 USDRegular priceUnit price / per

IS15152108Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', 12', & 14'

Shade Size Minimum-

60'

Shade Size Maximum

10'

-

Triangle Sail Shade

ES15151508Regular price $0.00 USDRegular priceUnit price / per

ES15151508Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', 12', & 14'

Shade Size Minimum-

60'

Shade Size Maximum

10'

-

Hyperbolic Sail Shade

HY202008Regular price $0.00 USDRegular priceUnit price / per

HY202008Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', 12', & 14'

Shade Size Minimum-

20'

Shade Size Maximum

35'

-

Quad Sail Shade

SQ101008IGRegular price $0.00 USDRegular priceUnit price / per

SQ101008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

10'

Shade Size Maximum

30'

-

Square Sand Dollar Sail Shade

SS202008IGRegular price $0.00 USDRegular priceUnit price / per

SS202008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

20'

Shade Size Maximum

36'

-

Kite Hip Sail Shade

Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

25'

Shade Size Maximum

10'

-

Hexagon Pinwheel Sail Shade

HPW202008IGRegular price $0.00 USDRegular priceUnit price / per

HPW202008IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

36'

Shade Size Maximum

12'

-

Square Pinwheel Sail Shade

SPW141408IGRegular price $0.00 USDRegular priceUnit price / per

SPW141408IGRegular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', & 12'

Shade Size Minimum-

30'

Shade Size Maximum

10'

-

Flower Shade

FF121210Regular price $0.00 USDRegular priceUnit price / per

FF121210Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

10' to 14'

Shade Size Minimum-

12'

Shade Size Maximum

15'

-

Halo Disc Shade

HALO-1511Regular price $0.00 USDRegular priceUnit price / per

HALO-1511Regular price $0.00 USDRegular priceUnit price / per

Entry Heights-

8', 10', 12', & 14'

Shade Size Minimum-

21'

Shade Size Maximum

15'

Collection: Playground Shades & Sails

Our shades are a testament to extensive design expertise and engineering precision, crafted from premium materials and utilizing state-of-the-art manufacturing processes. Here's a detailed look at how we meticulously construct our shade structures to ensure supreme quality and precision from conception to completion.

The journey of your shade begins with our specialized in-house design and engineering team, who possess the skills to tailor a shade solution that seamlessly integrates into your environment. They also guarantee compliance with local building codes.

Following the design and engineering phase, we commence production. The process starts with the cutting and sewing of the shade fabric, where our skilled artisans employ robust stitching techniques to create a resilient shade canopy. The steel for the frame is then precisely cut and expertly welded using reliable welding methods. Subsequently, the frame undergoes a thorough powder coating process, including priming with a zinc-rich primer and baking at 425°F, resulting in a marine-grade finish with 6-8 mils of primer and powder coating.

Concurrently, our innovative quick-release Glide Elbow mechanism is assembled and tested in the factory to ensure straightforward installation. The shade's tensioning cable is also precisely cut. Following these steps, the shade undergoes a rigorous final check before being carefully packed for shipping. Large steel components are securely placed on pallets, and smaller elements are individually wrapped, all safeguarded by shipping plastic to prevent transit damage. Typically, after a 4-5 week period of meticulous design, engineering, and manufacturing, your shade is ready to be dispatched to its new location, where it will provide lasting elegance and functionality.

Products faq's

The duration for acquiring a shade structure can differ based on the design's complexity and the structure type. The process generally divides into engineering and production stages. Typically, engineering takes 2-3 weeks, while production spans 4-5 weeks. Here's a closer look:

Engineering Phase: For custom shades not requiring sealed drawings, generating shop drawings/BOMs and preparing workloads usually takes 2-3 weeks. After this, the order moves to production, and an estimated shipping date is provided for installation planning.

Production Phase: When your order enters the production queue, there's often a backlog of three weeks' worth of shade orders. Building and shipping a standard order typically takes one week, meaning the total time from engineering completion to shipping is around 4-5 weeks. However, specific custom features, like unique powder coat colors, might extend this timeline due to vendor lead times.

Certainly, we can customize our shade structures to adhere to local wind requirements if they surpass our standard specifications, upon request.

The concrete needs for the shade structure vary based on several factors, including the structure's type and size, its location, and the elevation. Bigger structures or those with taller entry points typically require more substantial foundations to accommodate the increased load on the frame. Additionally, we can tailor the foundation design to align with your preferred installation approach, whether that involves a spread footer or a pier footing style.

Our standard shade structures, equipped with fabric, are built to endure sustained winds of 75 mph and 3-second gusts of up to 90 mph. Without the fabric, the frame alone is capable of withstanding winds of up to 150 mph. Should you require it, we can also engineer our structures to withstand even higher wind loads.

Our shade fabrics come with a ten-year limited warranty from the delivery date, covering significant fading, deterioration, breakdown, and damage from outdoor heat, cold, or discoloration. If a fabric replacement is necessary under the warranty, we will produce and deliver a new fabric at no cost during the initial six years. For the subsequent four years, replacements are pro-rated at 18% per annum.

View Other Popular Categories!

-

Nature Rocks Boulders & Climbers

Introduce an element of adventure and natural beauty to your educational play...

-

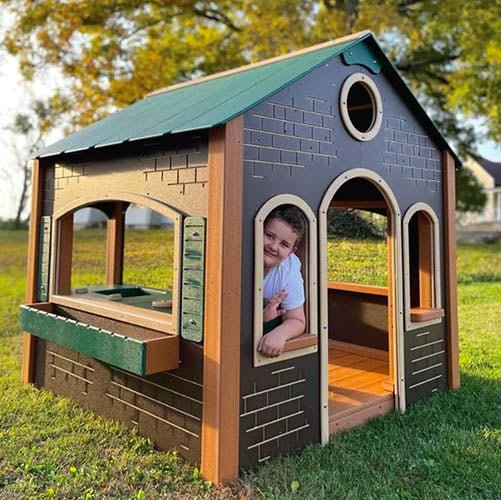

Dramatic & Imaginative Play

Step into the enchanting world of Playtopia's Dramatic and Imaginative Play Products,...

-

Outdoor Musical Instruments

At Playtopia Playgrounds, we are proud to present our exclusive range of...

-

Puddle Jumper Early Play

At Puddle Jumper, we understand the critical role play plays in early...

-

Swing Sets & Swing Seats

Explore the joy and developmental benefits of Playtopia's swing sets, designed for...